There was a time when manufacturing was all about muscle—hours spent working, machines running until they broke, and production schedules that were dictated by human instinct rather than real-time data. But as we stand on the brink of the future, manufacturing is no longer just about muscle. It’s about intelligence, precision, and insight. And the key to unlocking this new era of manufacturing is data.

Imagine a world where you can not only track every step of the manufacturing process but also predict what will happen next. A world where your equipment never breaks down unexpectedly because you knew exactly when to perform maintenance. A world where your team can collaborate, optimize, and innovate—regardless of where they are in the world. That world is not the future. It’s happening now.

The forces driving this transformation are IoT, cloud computing, and data analytics. These technologies are giving manufacturers a new kind of superpower—one that allows them to move faster, think smarter, and deliver products of unparalleled quality. But more than that, they’re allowing manufacturers to shape the future of an entire industry.

Welcome to the world of data-driven manufacturing.

The Heartbeat of Manufacturing: IoT and Real-Time Insight

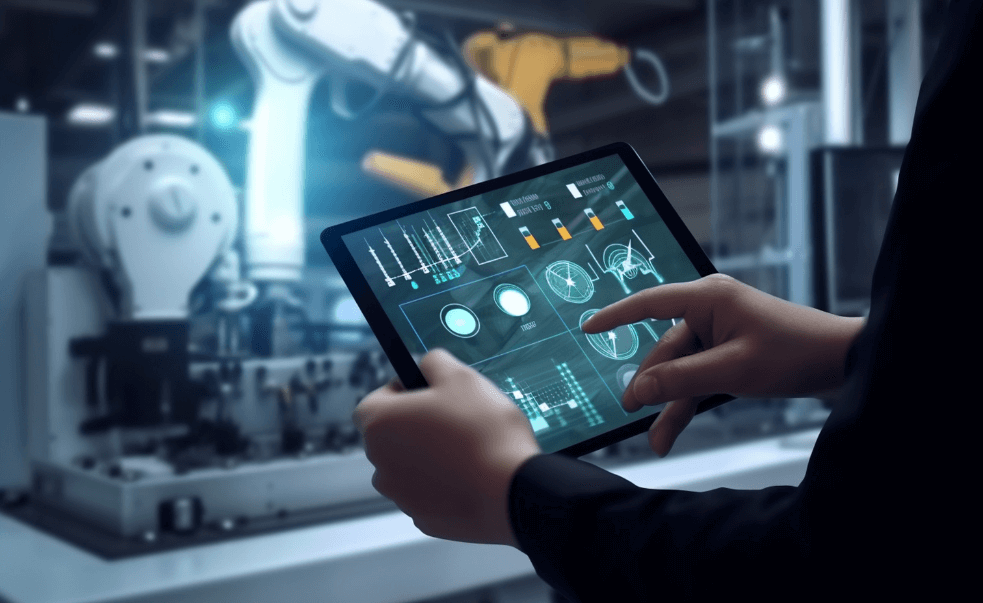

Imagine walking through a factory floor. You hear the hum of machines, the bustle of workers, and the rhythmic motion of conveyor belts. But beneath this surface, something else is happening—a constant flow of data.

That’s the power of IoT—the Internet of Things. IoT connects your machines, tools, and processes, allowing them to speak to each other. It’s like giving your equipment a voice, one that can tell you exactly what it’s doing, how it’s performing, and when it needs attention. In other words, it transforms your factory into a smart factory.

The Beauty of Real-Time Data

What if you could predict the future of your operations? What if you could see into the future of your machines, processes, and production lines? With IoT, this is no longer a fantasy. It’s a reality.

By embedding sensors in your machines, you can gather real-time data on temperature, vibration, speed, and more. This data flows back to a central system where it is analyzed and interpreted in real time. This allows you to make decisions based on facts, not assumptions. Think about the possibilities:

Predicting Equipment Failures: Instead of reacting to a breakdown, you can predict when and where a failure will occur. You can perform preventive maintenance to avoid disruptions, ensuring that machines keep running smoothly and production stays on track.

Predicting Equipment Failures: Instead of reacting to a breakdown, you can predict when and where a failure will occur. You can perform preventive maintenance to avoid disruptions, ensuring that machines keep running smoothly and production stays on track. Optimizing Operations: By continuously monitoring your production lines, you can identify bottlenecks, track performance, and adjust operations for maximum efficiency.

Optimizing Operations: By continuously monitoring your production lines, you can identify bottlenecks, track performance, and adjust operations for maximum efficiency.IoT brings clarity to your factory. It eliminates guesswork and replaces it with insights that empower you to act quickly, intelligently, and confidently.

Cloud Computing: Bringing Your Manufacturing Data Together

Think about the world we live in today. We carry smartphones in our pockets, access our bank accounts through apps, and work remotely from anywhere in the world. This global, connected world has redefined how we operate. But for manufacturers, the real question is: How do we bring this level of connectivity into our operations?

Enter cloud computing.

The cloud is more than just a place to store data—it’s a powerful platform that allows you to access, analyze, and share your manufacturing data in real time, no matter where you are. With the cloud, your factory floor can be connected to the entire world, allowing teams to collaborate across geographies and departments, all while accessing the same data, at the same time.

Why the Cloud Is a Game-Changer for Manufacturers

For manufacturers, the cloud is a game-changer because it provides unprecedented flexibility. No longer do you need to rely on physical servers that take up space and require constant maintenance. With the cloud, your data is stored securely, but it’s also instantly accessible from anywhere.

This creates a new level of agility. Imagine being able to view real-time production data from your phone while you’re on the road. Or having your entire operations team access critical performance metrics during a conference call—whether they’re in the office or at home. The cloud makes this possible.

Scaling with Ease

Cloud computing also allows manufacturers to scale as they grow. As your operations expand, you can increase your cloud storage and processing capacity without needing to buy new physical hardware. This gives you the freedom to innovate, grow, and adapt without worrying about your technology infrastructure.

Data Analytics: Transforming Raw Data Into Actionable Insights

Data is only valuable if you can understand it. And that’s where data analytics comes in. Data analytics is the process of taking all the raw data your systems are generating and turning it into insights that you can use to make smarter, more strategic decisions.

The Power of Predictive Analytics

One of the most exciting aspects of data analytics is the power of predictive insights. By analyzing historical data, you can forecast future trends and predict potential problems before they even happen.

Imagine being able to predict the demand for a certain product months in advance, allowing you to adjust your production schedule accordingly. Or using predictive maintenance to foresee when a piece of machinery will need servicing—long before it breaks down.

These predictive capabilities allow manufacturers to be more proactive and less reactive. Instead of waiting for something to go wrong, you can anticipate issues and make decisions that ensure your operations stay smooth, efficient, and productive.

Optimizing Your Manufacturing Process

Data analytics also allows you to optimize every part of your production process. By analyzing performance data from your production lines, you can uncover bottlenecks, improve workflows, and identify areas where you can increase efficiency.

For example, you might discover that certain machines run at less than optimal speeds in the afternoons. Or that certain materials perform better than others, leading to fewer defects. Armed with these insights, you can make adjustments that improve overall productivity and quality.

The Heart of Manufacturing’s Future: People + Technology

While IoT, cloud computing, and data analytics are the tools that drive manufacturing forward, they’re not the end of the story. The true power of these technologies lies in the people who use them.

The future of manufacturing is about empowering people to make smarter decisions, collaborate more effectively, and innovate faster. It’s about giving your team the tools they need to succeed, while encouraging a culture of continuous improvement.

In this new world, manufacturing isn’t just about machines—it’s about people, technology, and the possibilities that come when they work together.

A Vision for the Future: Smarter, More Efficient Manufacturing

The future of manufacturing isn’t just about making things faster or cheaper. It’s about making things smarter—more efficiently, more sustainably, and more collaboratively. It’s about empowering manufacturers to make the right decisions at the right time, using real-time data, cloud-based insights, and predictive analytics.

As we look to the future, one thing is clear: The world of manufacturing is changing. And those who embrace the power of data will lead the charge.

In this new world, success isn’t defined by how many products you make, but by how smartly you make them. It’s not just about productivity—it’s about precision. It’s not just about output—it’s about impact.

Embrace the Future Today

Manufacturing is at a crossroads. The world is changing, and the companies that thrive will be the ones that leverage the power of data to drive transformation. With IoT, cloud computing, and data analytics, manufacturers now have the tools to take control of their future and unlock new levels of efficiency, collaboration, and innovation.

The question is, are you ready to embrace the future? The time to act is now.

It’s time to unlock the future of manufacturing—and the future starts with data.